Frequently Asked Questions

-

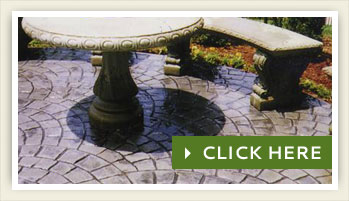

What is impressed concrete?

Impressed concrete is integrally coloured concrete impressed with special tools, materials and techniques to create decorative surfaces such as brick, fieldstone, cobblestone, etc. It is then sealed to prevent staining, fading and enhance the finish.

-

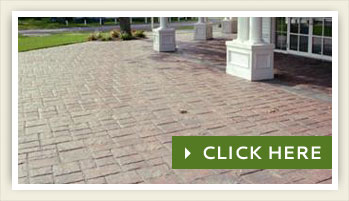

What is Textured concrete?

Textured concrete is integrally coloured concrete impressed with special tools, materials, and techniques similar to the impressed concrete system. Unlike the impressed concrete system, textured concrete has a more level surface allowing for a smoother finish where wheel chair use is required, for playing basketball, or any other area where a flatter surface is desired. The finished surface can be further enhanced through the use of coloured etching stains to give a marbleized appearance and by the use of a concrete saw to create diamonds, circles, borders, and other shapes. It is then sealed to prevent staining, fading, and further enhance the finish.

-

Will Textured or impressed concrete crack?

It is not unusual to see cracks in concrete, but impressed and textured concrete is poured using specifications for maximizing crack control, i.e. a)prepare a solid base, b)use a high strength concrete, c)reinforce with fibre and/or rebar, d)place saw cuts at least ¼ of the depth of the concrete and locate them at least every 6 feet. By following these specifications Impresscrete minimizes any risk of cracking.

-

For how many years has impressed concrete been installed?

The system for making impressed concrete is more than 40 years old, the chemistry having been proven in installations throughout the United States, Canada, and Europe, in both hot and cold climates. However, installations made prior to approximately 30 years ago were single colour, with no texture. They used now obsolete tools which only stamped in the joint lines but could not control their depth. Joint lines that were too deep posed a risk in northern climates due to pressure from water freezing in the joints and cracking off portions of the concrete surface. The impressed concrete system now uses a rubber type mat which controls the depths of the joints, gives texture and allows two colour systems to be used. With the improvements made to the tools, impressed concrete is now a reliable product for flat work and is a popular choice.

-

For how many years has Textured concrete been installed?

The application of textured concrete was created in 1998. It was developed to offer a different finish other than impressed concrete. The process of installing textured concrete is quite similar to the proven impressed installation.

-

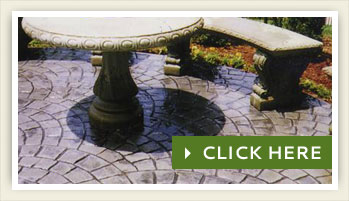

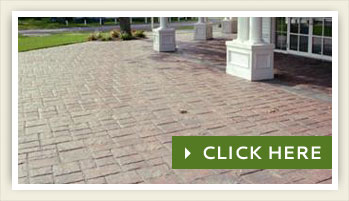

What are some uses for impressed or Textured concrete?

Impressed or Textured concrete can be used in all places where you would use plain concrete, but want a more decorative surface. Installations for residential use can be for pool decks, patios, walkways, and driveways. Commercial uses include entryways into hotels and other commercial buildings, walkways, showrooms, restaurants, etc. The possibilities are only limited by one's imagination.

-

How long will impressed or Textured concrete last?

Impressed and Textured concrete is durable as all concrete is. It will last for many, many years. If there is extensive wear on the concrete, you may want to give it the 'just like new' look by having it resealed.

-

How does salt affect impressed or Textured concrete?

Salt increases the occurrence of freeze/thaw cycles during the course of a winter season. Therefore there is an increased opportunity for it to cause damage to the surface. To alleviate this problem, impressed and Textured concrete is poured using a high strength concrete complete with air entrainment, suitable or superior to Ministry of Transportation specifications. The high cement content and air entrained concrete almost entirely reduces the ability for salt to do damage. To avoid potential surface damage, we suggest salt alternatives to aid in ice/snow traction problems that occur. Sand is the best, with ashes being equally as effective but far more dirty. For further protection, an acrylic sealer is applied directly to the surface of the concrete making snow and ice easier to remove.

-

What are the advantages of the impressed or textured concrete applications?

There are many advantages to impressed and textured concrete; they include the following:

a) No weeds. It is poured as one structural pad, which eliminates any chance of weeds growing through it. Therefore, there will be no pulling weeds, spraying weed killer, or mowing your driveway, sidewalk, patio, etc.

b) It maintains a level surface. Through the effects of freeze/thaw cycles, heavy rains and vehicles traveling over it, other applications may settle, pop up, or separate, posing liability risks.

c) Very low maintenance. Impressed and textured concrete's strength, durability, level surface and stability keeps maintenance to a minimum. It is recommended to reseal it periodically.

d) Cost. Impressed and textured concrete is comparable in dollar value to other applications on the market but lasts for many years, requires little maintenance and has a natural and unique appearance which makes it a wise choice.

VIEW OUR WORK

PRODUCT INFO

WHAT CUSTOMERS SAY